Better Nursery Practices to Produce High Quality Landscape Plants

At a glimpse: Discusses the Smart Pot in the winter in Maryland

By Stanton Gill & Susanne Klick, University of Maryland

From Groundwork, February 2005

Better Nursery Practices to Produce High Quality Landscape Plants

By Stanton Gill and Suzanne Klick

(Dr. Gill is the Regional Specialist, Central Maryland Research & Education Center, University of Maryland.

Dr. Klick is the Agricultural Technician, CMREC, University of Maryland) First published in GROUNDWORK, February 2005

GROUNDWORK is a publication of the landscape contractors association of Maryland, Virginia & D.C.

Landscape managers and nursery plant producers are always searching for the perfect production method that allows high success rate in transplanting trees. The search for the best method of tree growing and transplanting has been going on since people started moving trees into landscapes. The market drives the need for refinement and change in production methods.

The nursery business in Maryland has always been adaptable with managers willing to change their production methods to better suit the customer. What is the market demanding? In surveying landscape managers we are hearing that bigger trees (3” caliper and up) and plant material that can be installed over a wide range of the year is what they want. The strong Washington/Baltimore/Annapolis market has created a need for plant material in just about all of the seasons. Field grown plants have reigned as “king of production methods for years but field productions of plants is giving way to various methods of container growing plants.

Field produced plants still rank the number one preference of most landscape managers. No doubt about it, a good field grown, balled and burlapped (B&B) plant often has the best transplant rate for most tree species. The problem is that the ideal time for field harvest is limited to spring and fall with summer digging possible but at greater expense. Summer digging takes a fair amount of effort and usually involves a larger rootball and hardening off time. Even with its harvest limitation, field produced trees will continue to be an excellent way to produce quality plant material and the demand remains strong for good B&B trees and large shrubs.

In the 1990s pot-in-pot showed up on the nursery production scene. This growing method enabled nursery producers to provide plant material at most times of the year. The number of Maryland nurseries moving into pot-in-pot production is increasing steadily each year. A well grown pot-in-pot plant is often a very good product. Landscape managers now can pick between some of the common container sizes of 7 gallon, 15 gallon and even 30 gallon container grown trees and shrubs. The problem is that some very vigorous plant material rapidly fills the pot and results in circling roots. A plant with circling roots often just does not establish well in a landscape without a lot of pulling roots outwards.

In 1980, work began in Oklahoma on a modified method of growing trees in the ground. The idea was to develop a method of keeping a field grown plant’s roots contained within a small area and forcing the roots to branch and prune. Various weed barrier materials were sown into porous cylinders for these experiments, which took place at a wholesale nursery in Guthrie, Oklahoma owned by Ralph Reiger. Two years later, trees from the Guthrie farm were transplanted to Oklahoma State University, where additional studies were quickly initiated by Professor Carl Whitcomb. In 1984 Ralph and Carl formed a company, Root Control, Inc. and sold the first Root Control Bags in the nursery business. The first product introduced had many problems such as roots blasting through the plastic bottom or finding their way out through the seams. Whitcomb, working with Ralph and Kurt Reiger, of Root Control Company refined the product, making the seams stronger and less prone to root escape, and created a tougher bottom to the bag that keep roots confined. Root Control Company produces one type of root control bag made out of custom non-woven polypropylene. In the late 1980’s, Carl Whitcomb went off and established his own company called Lacebark Company which makes a root containment bag out of a different material. Nursery managers use both products, and there is brand loyalty among users of both root containment products.

Root Control Company produces a bag that is a non-woven polypropylene. The inside of the bag has what the company describes as a “fuzzy surface” that catches roots and prevents them from circling. Small roots penetrate the bag, but they are choked off as they increase in diameter causing a branching of root within the confines of the bag.

There are a number of Maryland growers that are producing plants in root containment bags. Small and medium size nurseries (10-40 acres) tend to utilize root containment bags but some larger operations use root containment for certain “hard-to-transplant” plant species. These root control bags have been especially popular for nursery managers growing Leyland cypress. Many landscapers report that summer and fall planted Leyland cypress grown in root containment bags perform better then field grown Leyland cypress. In the spring and early summer, the difference in transplant success between traditional field grown and root containment grown is less noticeable.

Container grown Leyland are transplanted at most times of the year. The most frequent observation of blown over Leyland cypress appears to be with plastic, container grown Leylands, especially if the root system was circling the pot when it was moved into the landscape. The Leyland cypress grown in root containment bags can be established at the same times of year that plastic container grown plants are transplanted. The advantage appears to be that the roots grow out of the rootball quickly and anchoring into the ground rapidly with less likelihood of blow over.

At the nursery end, installing root containment bags in the nursery takes extra effort at establishment time and involves augering a hole and keeping the sides of the straight as soil is backfilled and a liner tree installed. Establishment containment bags in the nursery can be painfully slow, but the harvest is relatively easy and can be preformed over a wide range of seasons. A straight nursery spade can be inserted around the edge of the root containment bag to cut off fine roots that penetrate the bag. The tree is then popped out of the ground with the spade. Some nursery managers use a forklift and tilt the blade and use them to slide under the bag and pop it out of the ground. The root control bag should be removed at this stage. If it was left on and a landscape manager placed the tree into the landscape, it would be confined to the root control bag and the tree would decline as it matured over the next couple of years. Caring, concerned nursery managers will remove the root containment bag and cover the root ball with untreated burlap and place it in a daisy basket.

Root control grown plants have one peculiarity. The rootball will be relatively light. The roots fill the ball and make up the major portion of the rootball volume. A two-inch caliber B&B dug tree will have a rootball that will contain a lot of soil and weigh 300-350 lbs. In comparison, a twocaliber grown in an 18” diameter root containment bag would have a rootball that weighs 120-150 lbs.

It is absolutely necessary that a root containment grown tree be staked or anchored. One new anchoring device was sent to be evaluated at CMREC in 2003 called the ‘Tomahawk’m (www.borderconcepts.com). A metal stake is driven into the ground on the outside of the rootball and a metal extension holds down the rootball. Interesting idea but you now have a large piece of metal struck in the ground in the rootball zone. This may be a problem if the tree ever dies and someone has to grind the stump out of the ground.

Regardless of the staking or anchoring system used, the root control grown trees will establish roots in the surrounding ground very rapidly and the staking should be removed much sooner than B&B trees moved into the same landscape situation.

Container Grown Plant Above Ground in Maryland?

In the winter of 2002, Kurt Reiger of Root Control Company approached us at the Centra Maryland Research and Education Center and ask if we would consider trying out the new above ground root containment bags called the Smart Pot. The Smart Pot looks like a typical root containment bag with a few exceptions. The bag is coated with a chemical that inhibits the Ultraviolet (UV) light breakdown of the fabric material. Also, the bottom of the root containment bag consists of a fabric bottom that allows small roots to grow through the bottom of the bag. Typical root containment bags that is inserted into the ground have a plastic bottom on the inside that prevents roots from penetrating the bottom of the bag. When you are growing in the ground, roots growing through the bottom would make it difficult to pull the bag from the ground.

The Smart Pot is designed to grow above the ground, usually on top of a weed barrier. The small roots that grow through the cloth bottom give it some anchoring so it is less likely to blow over in the wind.

The idea of the Smart Pot is you can a plant above ground and when roots reach the outside perimeter of the fabric bag they air root prune and branch within the confines of the bag. Theoretically, the majority of roots are kept within the confines of the rootball so they should transplant well. In Maryland, this has not seemed feasible since our cold winters kill roots of many landscape trees in pots that are sitting above ground.

At this same time, we had contact with Scott Loosen of Amaroo Enterprise Company of Temecula, California. Amaroo Company had designed a nursery growing box with open slits on the side and plastic ridges on the inside. The plastic ridges block circling roots from forming and the open slits cause air root pruning. The air root pruning creates a branched root system within the rootball.

The box is make from recycled plastic that is colored black and consist of four sides and a bottom that are clipped and bolted together in about five minutes. The boxes come in a 35, 75 and 125 gallon size containers. The boxes are pretty substantial but are relatively light in weight (12.5lbs for a 35 gallon box). The Amaroo boxes were supplied through Worthington Farm of Greenville, North Carolina, Tod Williams was our contact with Worthington Farms. In 2002 they supplied 24” (35 gallon) Tree/Shrub boxes. These boxes are made of recycled plastic and are delivered in five sections that are easily clipped and bolted together. The boxes have a series of slotted holes on the side that create an air-pruned root system. The insides of the boxes have plastic ridges that prevent the formation of circling roots. The plants are grown in the container above ground. When you are ready to harvest, just unbolt the wing nuts on the corners and pull the box sides off. The rootball can be slipped into a daisy basket lined with burlap and easily star-laced for shipment. The 35-gallon Amaroo boxes cost around $18.00/box. (More than 2000 and the cost drops to $13/box). This sound expensive but the box is re-useable and should last at least ten – twelve years. You can expect to grow a tree in the box for one – two years and then move it into the market.

The Amaroo box is designed for growing the tree then re-using the box for additional sets of trees. The plastic should hold up for 10 years according to Scott Loosen. The ones in our trial plots at CMREC are three years old and are holding up well.

The Amaroo boxes are filled with substrate and trees planted in the box. When roots expand and hit the side, they air root prune and remain within the confines of the box. When a tree is ready to go to the landscape market, the box sides are un-bolted and unclipped and the root ball is slid out. Most nursery managers place the rootball into a burlap lined daisy basket which is star laced. You end up with a root system that is pretty much intact but of quality similar to root containment grown plants.

We agreed to work with Root Control Company in testing out the Smart Pots and Amaroo Company with Amaroo boxes in above ground production using two popular screening plants, Leyland cypress and Thuja “Green Giant’.

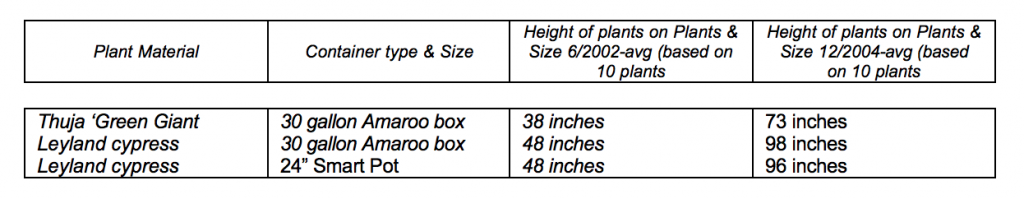

In the spring of 2002, we planted ten Leyland cypress of four foot height into 24” diameter Smart Pots from Root Control Company and ten Leyland cypress in the Amaroo boxes. We also planted three foot tall Thuja ‘Green Giant’ in the root containment bags. The substrate being a mix of 20% top soil, 40% leaf compost, and 40% milled pine bark. The plants in the Smart Pots and Amaroo Boxes were placed on weed barrier cloth. A trickle irrigation system was installed and the plants were fertilized with a slow release fertilizer of Nutricote 20-7-14.

Our intent in the winter of 2002/2003 was to surround the rootballs with wood chips supplied by a local arborist. Unfortunately, the arborist forgot about us until mid-January, and we had been through a couple of very cold spells. We decided that the plant material root systems were probably already damaged by the cold weather and decided that the trial would conclude at this point. Science often involves serendipity. We planned to get rid of the plants later in the season. In June, we started to remove one of the rootballs and found very little injury. In fact, the tops of the plants looked pretty good. By late June, the plants started producing new foliage and appeared to be growing as well as similar Leylands and Thuja growing in the ground at our research facility.

Temperatures were recorded over the winter of 2002 and 2003 using a temperature data logger. In 2003, the ambient air temperature plunged to 3 F for two days and rose to 5 F for three days. In January of 2004 the temperature dropped to 4 F and maintained a temperature of 4-5 F temperature recorded at 7:00 a.m. on each of these mornings. In the spring of 2004, we examined several Leyland cypress growing in the ground at nurseries in central Maryland and found that several branches suffered winter injury. We did not see similar injury on the Leyland cypress and Thuja ‘Green Giant’ growing in the Smart Pot.

We examined the root systems on the edge of the rootball after the winter of 2003 and 2004 and found a small amount of injury on perimeter roots. There was no scorching of leaves on any of the plants. Plant growth was strong during the summer months of 2003 and 2004. The plants in the Smart Pots and Amaroo Boxes had doubled in height over the two year period.

They grow well above Ground but do they transplant well?

We plant to grow the trees in the Smart Pots and Amaroo boxes for one more season. They will then be transplanted into the ground and evaluated for establishment. So far the roots systemsm look good with little if any evidence of circling roots in either the above ground Smart Pots and Amaroo box grown trees. We welcome anyone who wishes to visit the Central Maryland Research Center to take a look at the trial. Give us a call at 310-596-9413.